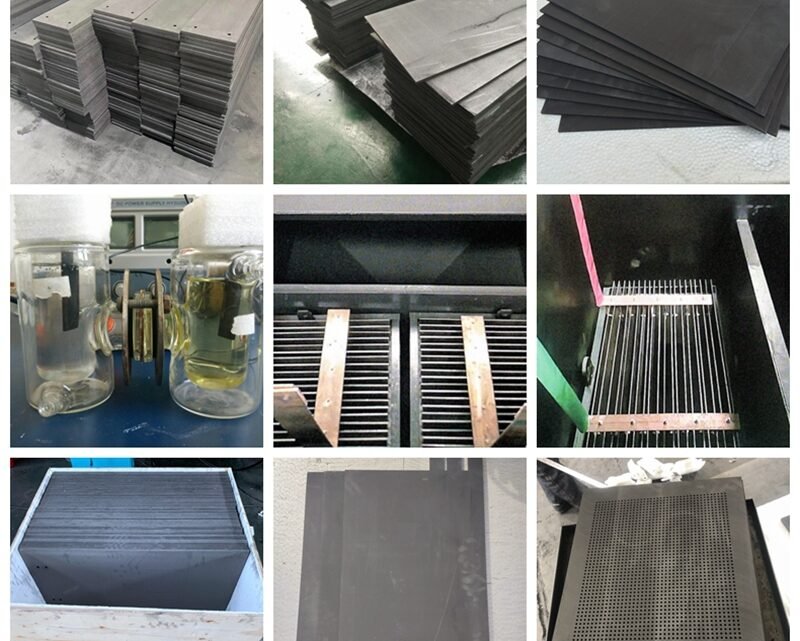

From the analysis of material properties, m106h is impregnated graphite, shore hardness is 60, compressive strength is $number. 6MPa, bending resistance 49MPa. Through the process test, the principle of micro-layer extrusion is adopted. The concrete method is: After the filtered micro-powder and kerosene are embedded into the grinding plate, the polishing plaster is used to remove the coarse particles from the surface of the flat plate, so that the micro powder particles on the surface of the slab are thrown flat and highly consistent. Then, the parts are directly placed on such a flat plate to grind, so that the flat plate can be uniformly uniform micro-layer extrusion cutting.Machined Graphite Parts

根据材料性能分析,m106h 为浸渍石墨,邵氏硬度为 60,抗压强度为 $ 数。6MPa,抗弯强度 49MPa。通过工艺试验,采用微层挤压原理。具体方法是: 将经过过滤的微粉和煤油嵌入磨盘后,用抛光石膏去除平板表面的粗颗粒,使平板表面的微粉颗粒抛平且高度一致。然后,将所述零件直接放置在这样的平板上进行研磨,使所述平板能够均匀地进行微层挤压切割。机加工石墨零件

The W7 Micropowder is still in the same order. After the completion of the study, the 200mm first-level knife-edge inspection, should not be transparent or uniform indentation; also available f80mm optical flat-crystal inspection, should be less than a light wave interference band, and uniform micro-convex. Should note: After the coarse, refined to the research, there are a large number of micro-powder embedded in the plate pores, the micro-powder to the cutting of graphite is enough, no longer the pressure sand process.Machined Graphite Parts Polishing plate. 4 layers of silk in a piece of already developed flat, with kerosene to the silk cloth poured through, and then with the W7 chromium oxide polishing paste will be another 2 pieces of the tablet on the silk cloth polished. The effect of polishing is to throw off the coarse particles on the plate and make the micro-powder distribution of the embedded plate highly consistent. At the same time, the surface roughness of the plate is improved, which is smaller than Ra0.1μm.Machined Graphite Parts

W7 微粉还是同样的顺序。研究完成后,对 200 毫米一级刀口进行检测,不应有透明或均匀的压痕;也可用 f80 毫米光学平晶进行检测,应有小于光波干涉带,且微凸度均匀。应注意: 经过粗加工、精加工后,有大量微粉嵌入板材孔隙中,微粉对石墨的切割就足够了,不再进行压砂加工。机加工石墨零件抛光板。4 层丝绸在一块已经展开的平面上,用煤油将丝绸倒入其中,然后用 W7 氧化铬抛光膏将另外 2 块平板上的丝绸抛光。抛光的作用是抛去板上的粗颗粒,使嵌入板的微粉分布高度一致。同时,改进了表面粗糙度,使其小于 Ra0.1 μm。机加工石墨零件

This process is the key to this method. On the polished 2-piece flat on the $number drip kerosene and instrumentation oil, with cotton oil on the plate daub evenly, after 3min, the flat surface of the oil layer wiped clean. In this way, the kerosene and micropowder in the permeable plate pores are uniformly mixed to form a micro-layer cutting fluid for processing graphite.Machined Graphite Parts

这个过程是这个方法的关键。在抛光的 2 片平板上滴上 $ 数煤油和仪表油,用棉花油在平板上均匀涂抹,3 分钟后,将平板表面的油层擦干净。这样,可渗透板孔中的煤油和微粉均匀混合,形成加工石墨的微层切削液。机加工石墨零件

The part is put on the plate to carry on the circular spiral movement, the two hands force is consistent, through the micro-layer extrusion cutting, completes the plane b the grinding. Pay attention to clean the plate, in time to remove the debris and dirt. After the completion of the parts, with a clean silk cloth or cotton wool lightly rub to grind debris. Attention can not be used to clean oil, the test found that after the oil immersion, the surface roughness of the parts become worse.Machined Graphite Parts

零件放在平板上进行圆弧螺旋运动,两手受力一致,通过微层挤压切割,完成平面 b 的磨削。注意清洁盘子,及时清除杂物和污垢。部分完成后,用干净的丝布或棉毛轻轻摩擦以磨碎碎屑。注意不能用来清洁油污,试验发现油污浸泡后,零件的表面粗糙度变差。机加工石墨零件